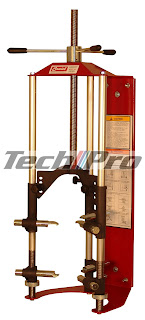

On the off chance that you anticipate

revamping the motor in that old authority auto or truck of yours, there is one

strength instrument that you will absolutely require: a valve spring

compressor. Without this particularly planned device, it will be for all

intents and purposes inconceivable for you to expel the valves from the barrel

head. With a specific end goal to expel the admission and fumes valves, the shop

spring compressor that holds every valve set up must be packed. Once the spring

is lessened in stature (which is typically just around 3/sixteenth of an inch),

the two-piece neckline (frequently alluded to as guardians) that fits around

the notch encompassing the highest point of the valve stem can be discharged,

the spring retainer lifted off and the valve expelled from the chamber head by

sliding it down the valve manage.

It's an exceptionally basic process;

however without a shop

spring compressor / equipment, unless you're Superman, you won't have the

capacity to do it. The most widely recognized sort of valve spring compressor

is the manual U-molded compressor. This apparatus is completely customizable in

it’s achieve so it can fit over an assortment of barrel heads, and has flexible

forks so it can be custom-made to fit an assortment of valve spring

measurements. The main drawback to this kind of compressor is that the chamber

head must be expelled from the motor. The normal cost for one is around $40; be

that as it may, at a current Carlisle swap meet, the frequently observed

apparatus merchant close to the sustenance court was offering no-name.

Truth be told, so powerful is this

instrument it took me around 20 minutes to expel the eight valves from my

Triumph's barrel head. For around $7, you can buy from your nearby car parts

store a straightforward valve spring compressor fork that depends on the

support technique for discharging the springs' strain. Made of thick, squeezed

sheet-metal, the 12-inch-long fork turns on one of the bordering rocker shaft

studs, where it is held in position by a solitary nut that screws onto the

stud. By pulling the fork towards you, the contrary end presses the valve

spring down, enabling you to evacuate the two managers holding the spring set

up. This sort of hardware requires far more prominent exertion than the

beforehand said compressor, so it can be somewhat hard to utilize, particularly

with stiffer, rivalry write springs or on double spring setups. The other

disadvantage is that the fork's opening on the valve spring end is

non-customizable, making it difficult to use on little dislodging motors that

utilization little measurement springs, yet it works fine and dandy.

0 comments:

Post a Comment